Drive In Pallet Racking Brisbane & Gold Coast Modular Storage Systems

Whether a seasoned pallet racking user or just a beginner, Rack 101© offers new insight for you that can be used to optimize the design of your next system. Begin Designing Your Pallet Rack System. Pallet racking is a high performance structure. Pound for pound, it is expected to perform greater than a building and should not be considered.

Pallet racking A flexible warehouse solution CLN Racking

1. Pallet Size and Type Pallet weight and dimensions (length, height, width) are essential measurements to be aware of when designing the layout of a pallet racking system. The industry standard pallet size (40" x 48") is a universal fit for the majority of systems.

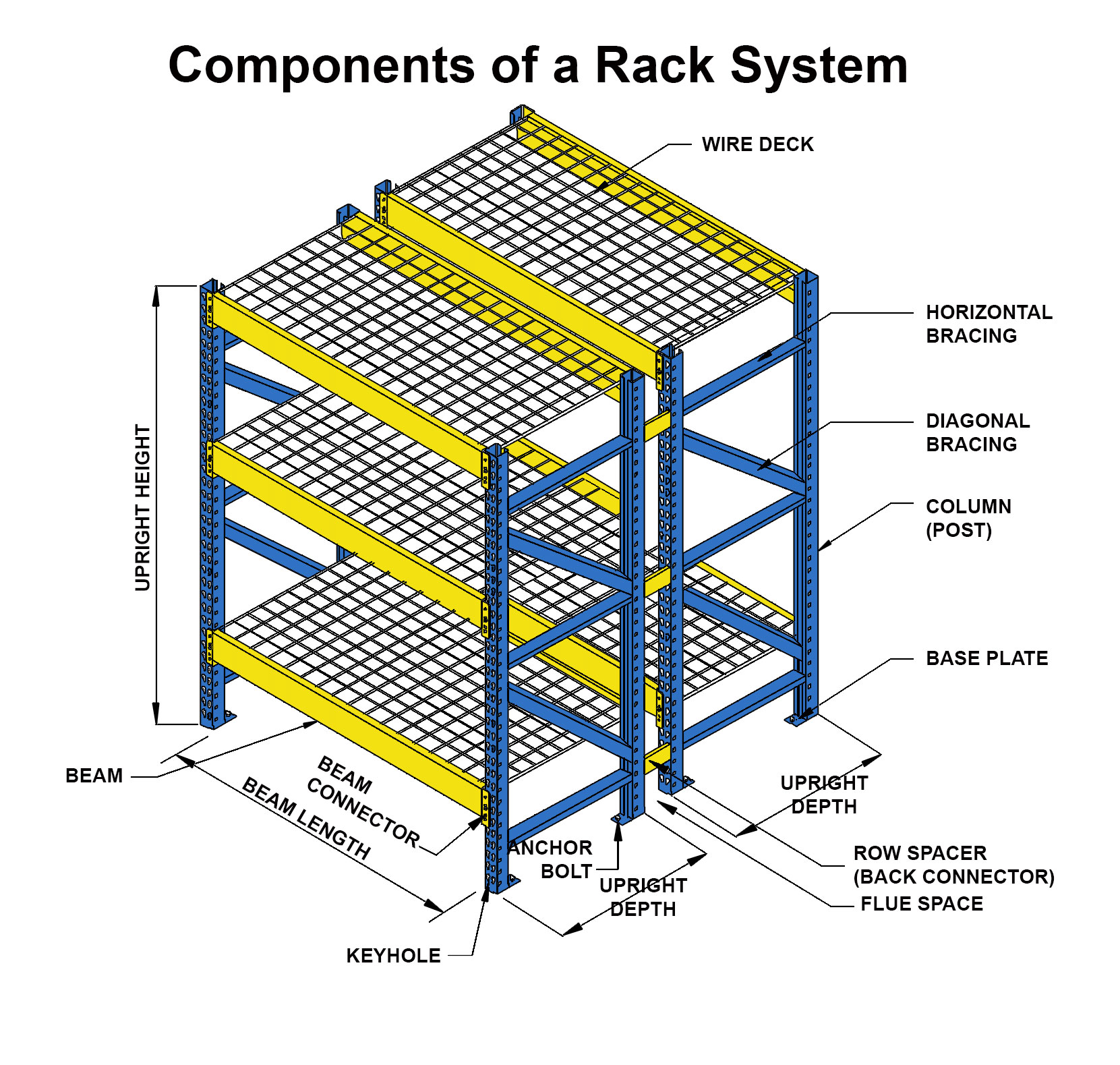

Components of a Pallet Rack System

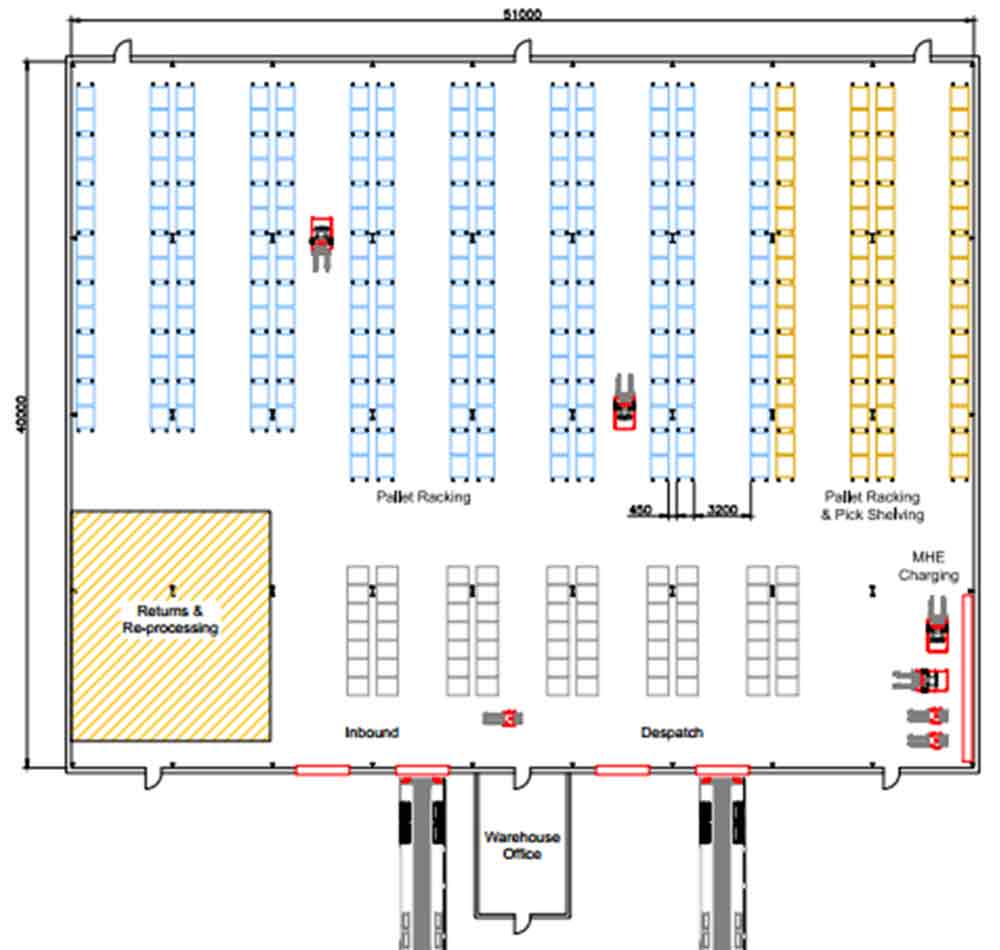

Design the layout to reduce the distance workers travel and increase product retrieval speed. Place frequently picked items near the front of the rack and ensure there is enough space between racks for easy movement of workers and equipment. Use a high-density pallet racking system such as drive-in or push back to maximize space utilization.

7 Tips for the Perfect Warehouse Layout Speedrack West

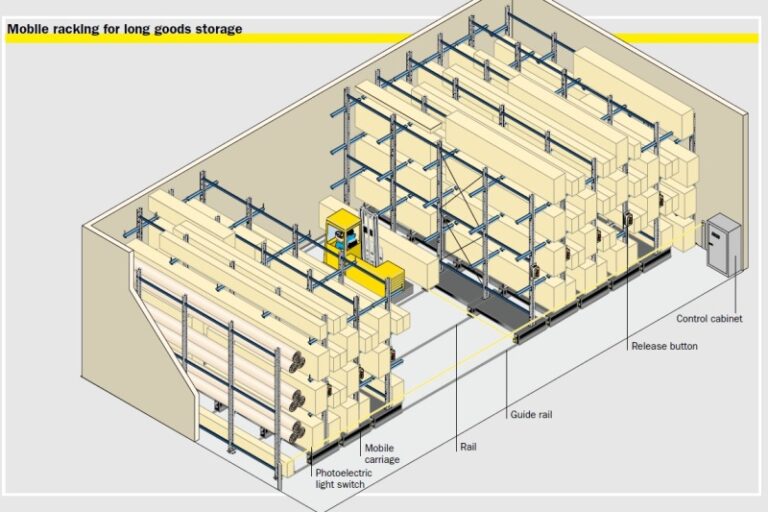

Pallet racking is currently the most popular solution, and it is also one that includes well over a dozen separate, often customizable configurations. This allows for adaptability in a warehouse's infrastructure, one that is especially valuable during unexpected peaks.

Design and CAD Drawings Softwares Canadian Rack Technologies Inc.

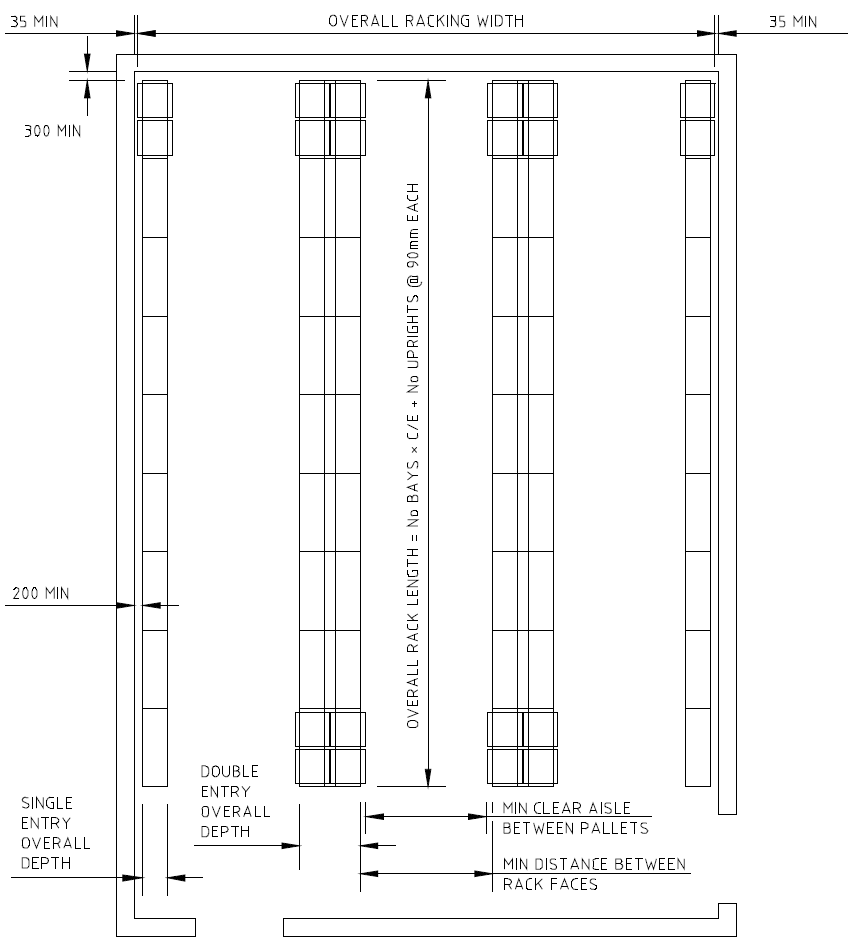

1. Double-Deep Racking Double-deep racking is a type of selective racking where you place pallets on a stationary shelf, allowing access to any pallet without moving the others. Unlike conventional selective solutions — which stack shelves just one pallet deep — this method uses two back-to-back rows.

Pallet rack plan detail dwg file. Cadbull

A pallet racking layout is essential for every warehouse to function properly. Without it, everything will be cluttered, and products will be hard to find. Designing pallet racking can be a complicated process if you don't know what you're doing, though. You won't just have to worry about keeping it organised, but also the pallet racking.

Pallet Racking Design and Layout l Advanced Handling & Storage Ltd

Pallet Racking Design - Cost Effective Ways to Optimise Your Racking Layout 20th September 2018 Adjustable Pallet Racking (APR) pallet racking continues to be the most popular warehouse racking solution used in the UK - possibly because its seen as the easiest to design and the cheapest racking to buy.

9 Things to Consider When Designing a Warehouse Pallet Racking System

Free, no-obligation pallet racking design and layout service throughout the UK. Our design team work to make the best use of your warehouse space.

Warehouse Pallet Racking Layouts for Buildings with Wide Column Spacing

Pallet racking with assisted stock rotation works on a First-in First-Out (FIFO) basis, which means the fist pallet loaded into the racks will be the first to be picked resulting in automatic stock rotation.

PALLET RACK Design Layout warehouse racking system design

🏗️🏬📦 Enter some data and immediately receive the complete drawing - find out the smartest pallet racking solution, that's what warehouse-planner does. Fill building with aisles Y ↕ Fill building with aisles Column to Column Y ↕↕↕ Explode rack blocks Fill building with rack fields X ↔ Calculate building

How to Make An Efficient Warehouse Racking Layout For Your Business

Home Pallet Racking Technical Articles Warehouse Racking Layout Warehouse Racking Layout Designing the right layout for your pallet racking or shelving not only increases your storage capacity but can improve your productivity too.

Shop Warehouse Pallet Rack Systems Atlantic Rack

What is pallet racking? Standard Pallet racking is a system of warehouse storage. It uses racks to enable pallets, on which goods and materials are stored, to be stacked vertically and horizontally for efficient use of space and full selectivity.

How to design a warehouse racks layout in six easy steps. Pacific Bend

In any Pallet Racking layouts there are four components: 1. The space occupied by the goods and the equipment on which they may be stored, with the necessary clearances. 2. The aisles between the goods, for direct access to the goods. 3. The gangways at the right angles to the aisles. 4.

Warehouse Guide Intro to Pallet Racking & Warehousing

However, minimum beam spacing to meet national fire code with a 40" wide pallet is 92 inches. The height-to-depth ratio of storage rack also is very important to keep in mind. Typically, a 6:1 height to depth ratio is deemed to be stable, eliminating the need for cross aisle ties. With specially designed racking, that can be pushed to 8:1.

How to design a warehouse racking layout for your business?

Once the pallets arrive, what would the flow be like, where would they go and what is their journey? The team should make sure that the shipment is correct and moved to a designated racking system where it can be stored until used in the outbound process.

Pallet Racks Buying Guide

Pallet racking systems are a storage method that leverages vertical space to store products and materials, whether single items or palletized loads. Operators typically use forklifts to place and retrieve pallets and other materials stored on the shelves. A typical warehouse pallet racking setup